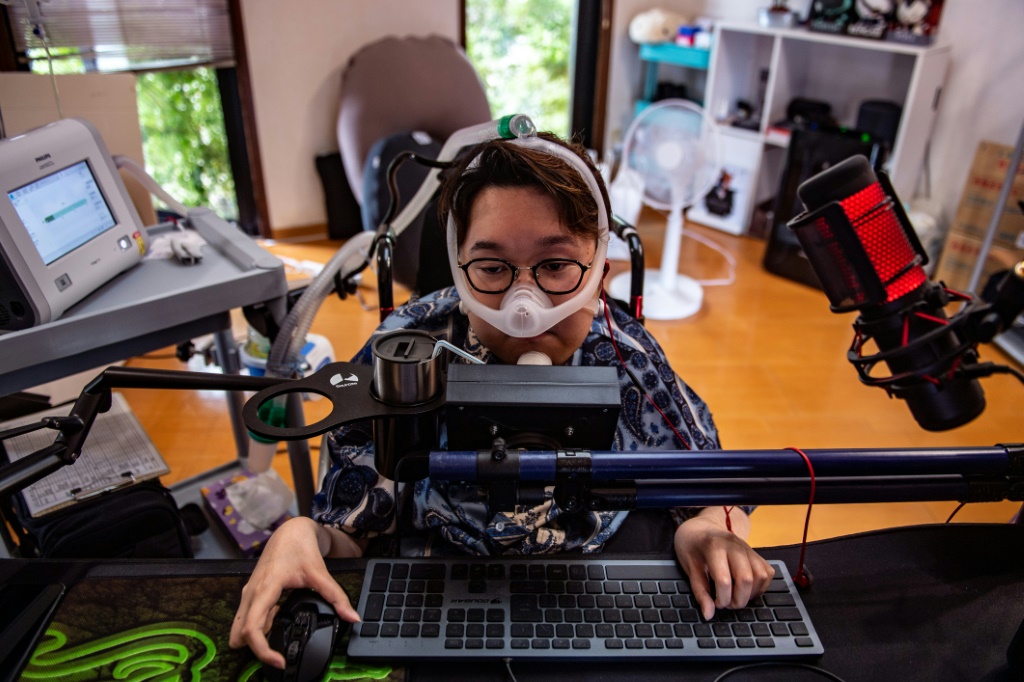

Last year, Shunya Hatakeyama and a friend designed a custom controller he could use with his chin. — © AFP

The global esports market is reported to be worth over $1.3 billion in 2022, with hundreds of gamers worldwide. Hence innovations in the esports space potentially lead to lucrative developments for the companies involved.

As the esports industry continues to expand, one technology start-up has seen an opportunity that could change the future for players and gaming enthusiasts. By working with 3D printing experts from Hubs.com, the Canadian start-up Formify has been able to develop and manufacture custom-fitting and lightweight ergonomic gaming mice. The objective is to help enhance player comfort and control.

Commenting to Digital Journal, Alex Cappy, CEO of Hubs, states: “Gaming is an enormous market that’s intrinsically tied to consumer electronics manufacturing. However, personalized design is still not an essential part of manufacturing for gaming. This presented an opportunity to the Formify team to bring unique, custom products to an industry sorely in need of such hardware innovation.”

Development costs for any 3D printing process will vary. 3D printing can cost anywhere from $3 up to thousands of dollars. Deciphering the precise cost of a 3D print requires a 3D model. Factors such as material, model complexity, and labour affect the price of 3D printing. 3D printing services can sometimes cost more than an entry level 3D printer.

In developing the technology, the company identified a gap in gaming and esports. Peripherals like mice and VR headsets were one-size-fits-all. Formify’s idea was to address this challenge was to develop a software platform that would transform a photo of a hand into a form-fitting mouse design.

The concept works by a customer submitting a photograph of their hand. This enables allowing the firm to analyse the shape, bone and joint structure, in order to design a product that provides maximum comfort and speed.

Innovations in 3D printing and customisation are being considered across an array of industries and products. Examples are: Hoe designs, furniture, wax castings for making jewellery, tools, tripods, gift and novelty items, and toys. Esports represents the latest area for innovation.

The next step utilises 3D printing to produce the mouse itself. Other manufacturing processes generally used for electrics, such as injection moulding, are better suited for higher volumes of identical parts from both cost and design standpoints.

For the 3D printing technology Formify settled on Multi Jet Fusion (MJF), due to the company being able to realise complex geometries. This led to 15 MJF-printed beta products being manufactured and tested.